Manufacturing

Ensuring R&D and Manufacturing have the exacting tools available to them during product development testing and ongoing manufacturing compliance testing

PHABRIX offers exceptional ‘in house’ test and measurement solutions for product development and technology manufacturing.

Compliant source generation, physical layer analysis and stress testing I/O interfaces are common key requirements for demanding in-house product development. It is important that supporting technology offers intuitive multi-instrument analysis to optimise efficiency and productivity during the development phase.

With the industry’s steady migration from traditional HD-SDI to 12G-SDI infrastructures, HDR/WCG and IP solutions, video technology manufacturers are now faced with the significant challenge of having to comply with a wide array of formats and new standards.

It is vital that test and measurement instruments offer automated multi-standards compliance checking, scripted automated tests and reporting of errors to ensure cost-effective, efficient and reliable test environments.

Key Features

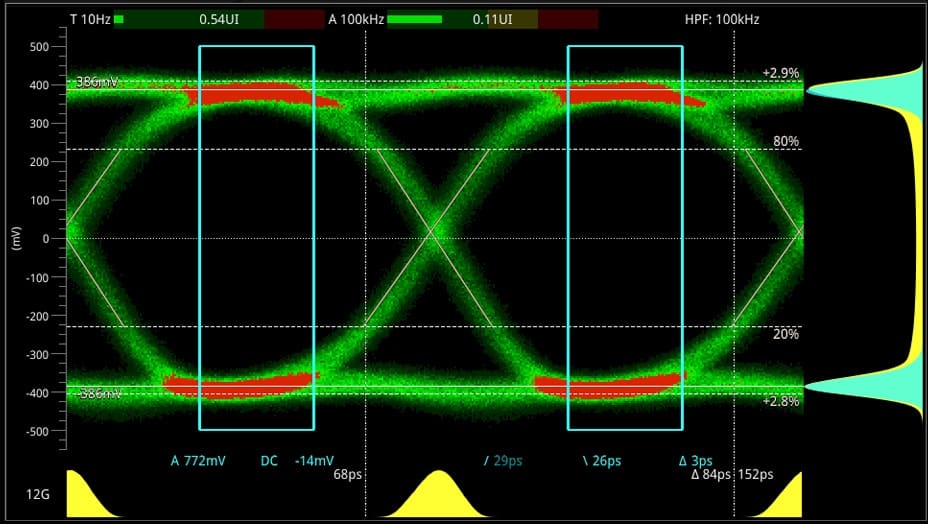

Fast, automated 12G-SDI physical layer analysis and advanced SDI stress testing

The Qx Series’ physical layer toolset offers fast 12G/6G/3G/HD-SDI physical layer testing, with its RTE™ (Real-Time Eye) technology instantly highlighting any SMPTE compliance issues. An advanced SDI-STRESS option is available for stress testing SDI interfaces up to 12G. The Qx series has built-in automation control allowing scripted testing to be performed faster, more reliably and at a lower cost.

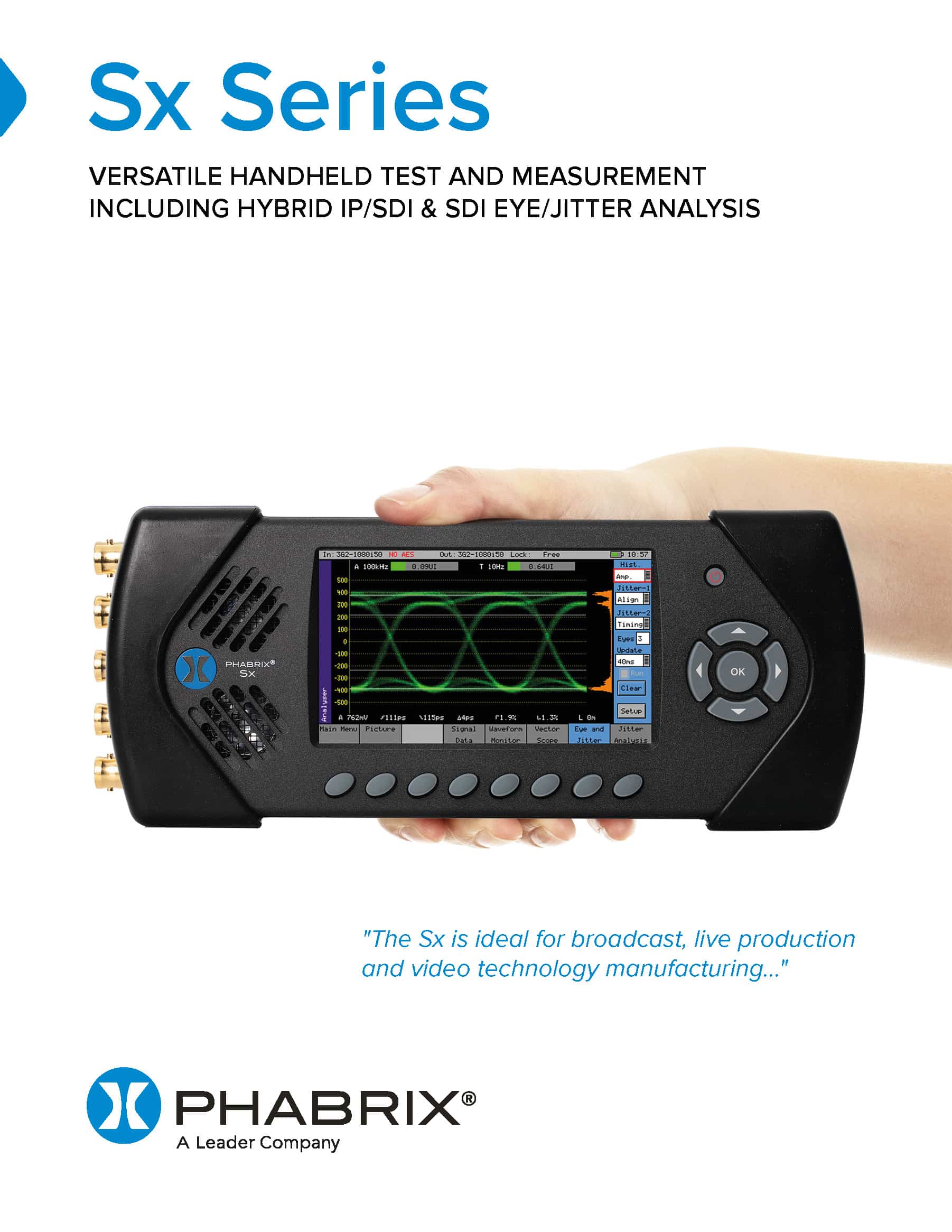

Handheld instruments for advanced physical layer and compliance testing

For manufacturing environments demanding a high level of portability, PHABRIX’s Sx Series offers hybrid IP/SDI testing, as well as advanced physical layer testing. The instant, RTE™ (Real-Time Eye) technology available in the SxE speeds physical layer testing and delivers automated measurements and logging for key parameters. The Sx Series supports over 350 formats for compliance monitoring as well as offering a TCP/IP interface for remote control and automated testing.

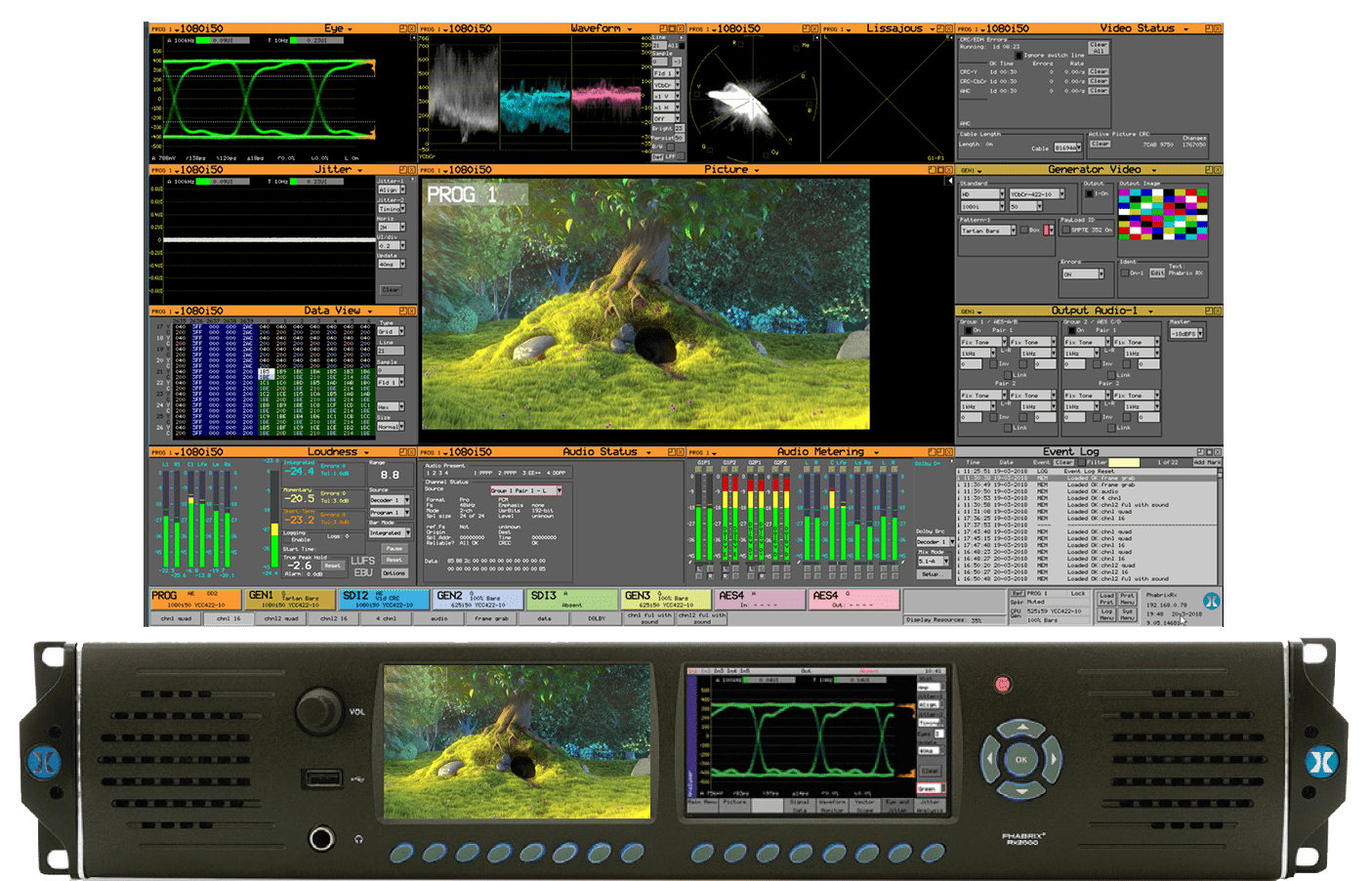

Single instrument 2K/3G/HD/SD rack-mount solutions for broadcast manufacturers

Available in 2U and 1U rack mount profiles, the Rx is already installed in many broadcast manufacturers around the world. With its combined video and audio toolset, the Rx offers faster intermittent fault diagnosis with video and audio capture with automated triggering, up to 4 channel physical layer analysis for testing SMPTE compliance issues as well as a TCP/IP interface for remote control, automated testing and test reporting.

RELATED PRODUCTS

QxP

The Portable QxL - 25G ST 2110 & 12G-SDI Generation, Analysis & Monitoring with Battery Power

Qx

Advanced Rasterizers for Hybrid IP/SDI, 4K/UHD, HDR/WCG Generation, Analysis & Monitoring

SxE

Portable 3G/HD/SD Generation, Analysis & Monitoring with Advanced Physical Layer Analysis

WHITEPAPER: Using Pseudo-Random Binary Sequences to Stress Test Serial Digital Interfaces

In this whitepaper, PHABRIX discusses the use of pseudo-random binary sequences (PRBS – also referred to as pseudo-random bit sequences), along with bit-error rate tests (BERT – also referred to as bit-error ratio tests) to stress test serial digital interfaces. The purpose of any physical layer serial digital interface (PHY) is to transmit or receive data whilst preserving that data’s integrity.

Lets Keep In Touch

Find Us, Follow Us, Keep In Touch

Our Latest News Direct To Your Inbox

Products, Software, Events and More